-

Позвоните нам 0592 6536915

-

Свяжитесь с нами по электронной почте sophia@fzolink.com

Table of Contents

1. Understanding the IP Rating System: Beyond the Surface Level

2. Decoding the Two Digits: Ingress Protection Explained

3. Comparing IP67 to Lower or Unrated Standards

4. Material Science: The Structural Superiority of IP67 Connector Housings

4.1. Gasket, Seal, and O-Ring Integrity

4.2. Housing Materials: Durability Against Physical Stress

5. Performance Metrics: Where IP67 Delivers Quantifiable Advantages

5.1. Reliability in Wet and Dusty Environments

5.2. Thermal Stability and Operational Range

6. Implementation and Maintenance: Choosing and Leveraging IP67 Solutions

6.1. Installation Best Practices for Maintaining the Seal

6.2. Lifecycle Cost Analysis: Investment vs. Replacement Frequency

7. Conclusion: Future-Proofing Connectivity with Ingress Protection

Connectors may seem simple: plug them in, and the system works. But in harsh environments like manufacturing facilities or rainy outdoor fields, a faulty connector can trigger costly operational disruptions. Standard connectors degrade rapidly when exposed to dust or water, while IP67 connectors solve this critical pain point. They provide complete dust-tight protection and can withstand temporary immersion in water up to 1 meter deep for 30 minutes—this level of ingress protection is invaluable for industrial, outdoor, and tech setups where equipment failure leads to significant time and financial losses.

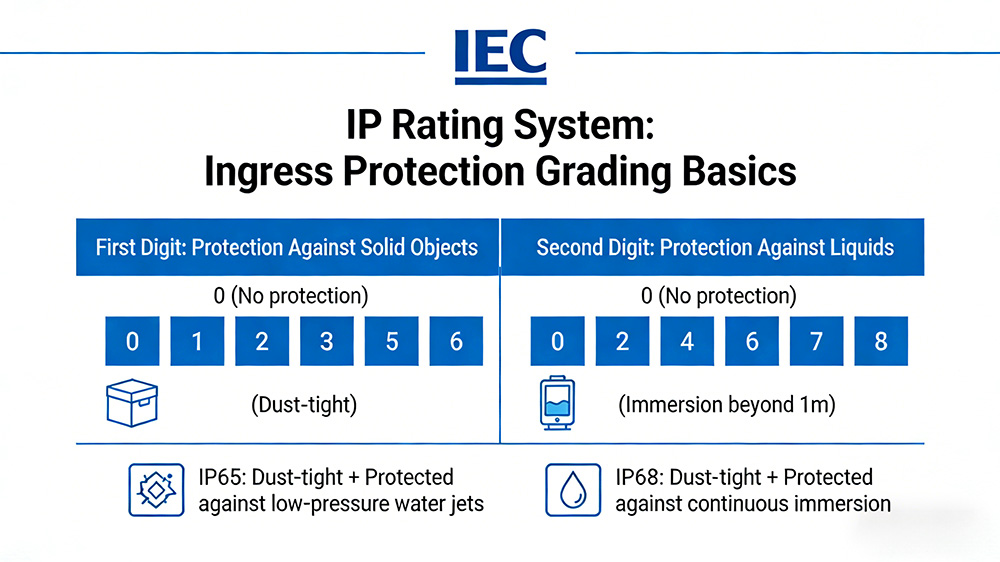

1. Understanding the IP Rating System: Beyond the Surface Level

IP (Ingress Protection) ratings quantify a device’s resistance to solid particles and liquid intrusion, established by international standards bodies such as the IEC (International Electrotechnical Commission). This standardized rating system enables buyers to select components engineered for long-term reliability in real-world operating conditions.

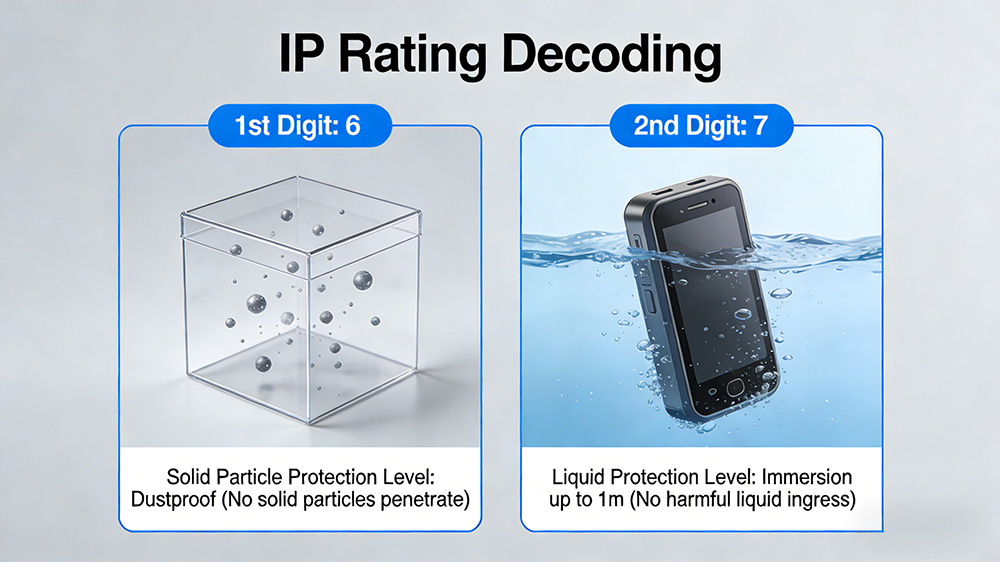

2. Decoding the Two Digits: Ingress Protection Explained

The first digit in an IP rating indicates protection against solid objects; a rating of 6 means complete dust tightness, preventing even fine particulate matter from entering the connector—even under pressure. This eliminates grit-induced wear on internal contacts, a common cause of gradual performance decline.

The second digit covers liquid resistance; a rating of 7 allows temporary water immersion. This means the connector can survive splashes or shallow flooding without short-circuiting, validated by rigorous testing where the unit is fully submerged in water to check for leaks.

By contrast, standard unrated connectors lack this engineered protection. Dust infiltrates quickly, leading to internal corrosion, while moisture seeps through structural gaps—causing immediate sparks, contact failure, or total system shutdown.

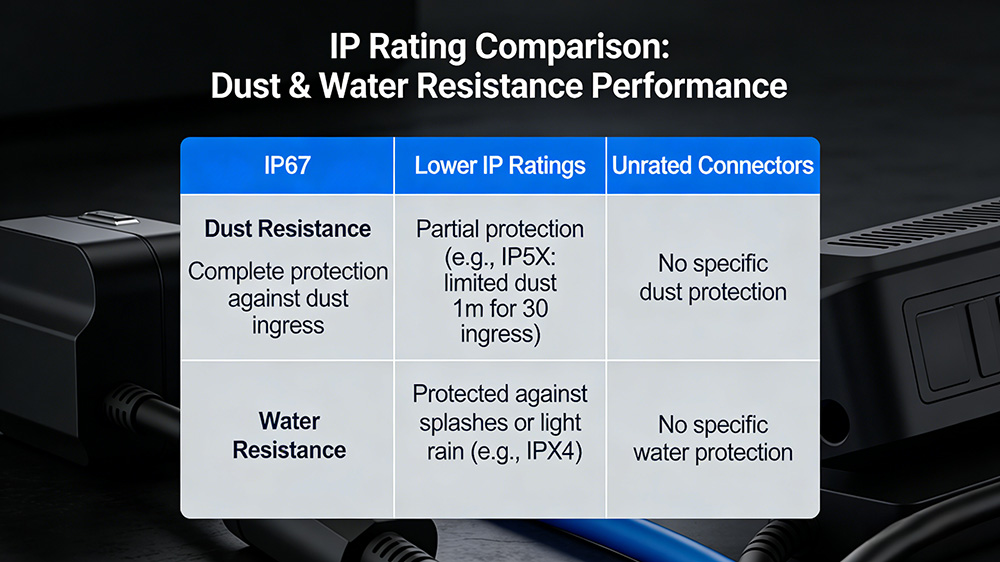

3. Comparing IP67 to Lower or Unrated Standards

Lower IP ratings offer only partial protection: IP44 blocks large splashes and coarse solids, suitable for mild indoor/outdoor use but ineffective in heavy dust or deep water. IP54 upgrades dust resistance but still permits minor particulate entry.

IP67 represents a definitive step up, with full dust sealing and certified immersion resistance—backed by lab testing that confirms no water ingress after 30 minutes at 1 meter depth. Unrated standard connectors, by comparison, often develop rust and corrosion in just a few weeks of outdoor use.

In practical applications like construction sites, IP67 connectors maintain consistent reliability, while lower-rated alternatives require frequent replacement. This stark performance gap is why IP67 is the gold standard for harsh-environment applications.

4. Material Science: The Structural Superiority of IP67 Connector Housings

IP67 connectors deliver durable performance through engineered design, with high-grade materials and precision sealing that stand up to daily mechanical stress and environmental exposure—without compromising connectivity.

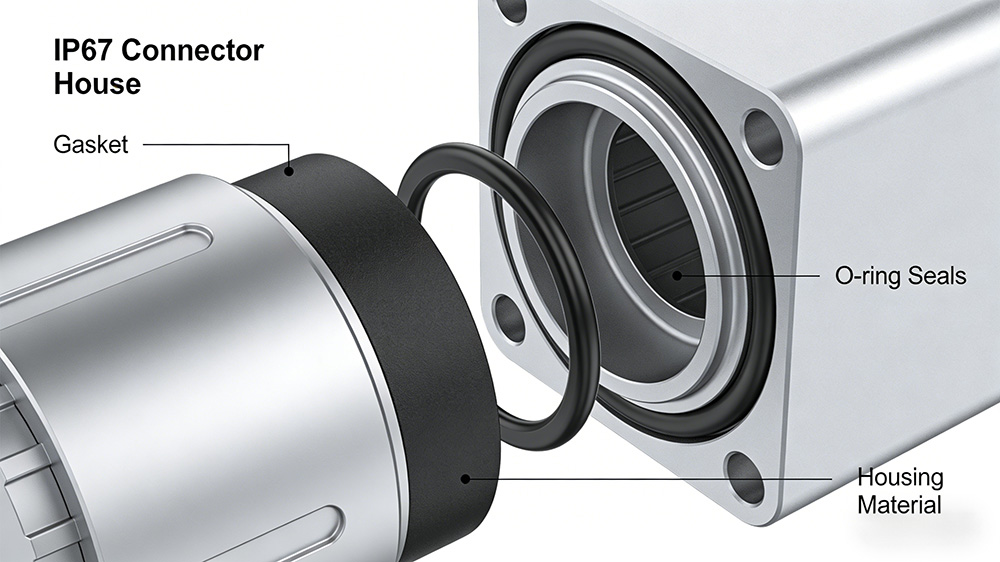

4.1 Gasket, Seal, and O-Ring Integrity

IP67 connectors integrate high-performance rubber or silicone seals and O-rings, which form a tight barrier around pin contacts to block all water and dust entry paths. Gaskets compress upon connection, filling microscopic structural gaps for a hermetic seal.

These sealing components are rated for extreme temperature fluctuations (-40°C to 85°C), resisting cracking, shrinking, or hardening over time. This eliminates capillary action—the primary cause of moisture intrusion in poorly sealed connectors—by creating an impenetrable barrier.

Standard connectors, by contrast, use low-cost foam seals that absorb moisture rapidly. Over time, these cheap seals degrade and fail, opening the door for dust and water ingress.

4.2 Housing Materials: Durability Against Physical Stress

IP67 connector housings are typically manufactured from die-cast zinc or aluminum—metals that withstand impact from tools, accidental drops, and rough handling without denting or warping.

For chemical-resistant applications, high-grade plastics like polycarbonate are also used, offering resistance to industrial chemicals, oil, and solvents. Both metal and plastic IP67 housings are engineered to resist vibration from heavy machinery, ensuring the connector remains securely mated and functional.

Basic standard connectors rely on low-quality PVC or nylon housings, which bend or crack under impact, degrade when exposed to industrial chemicals, and become brittle quickly under UV light—making them unsuitable for outdoor or factory use.

5. Performance Metrics: Where IP67 Delivers Quantifiable Advantages

Tangible data validates IP67’s superior performance, with measurable reductions in equipment failure and significant improvements in operational uptime. Key performance advantages include:

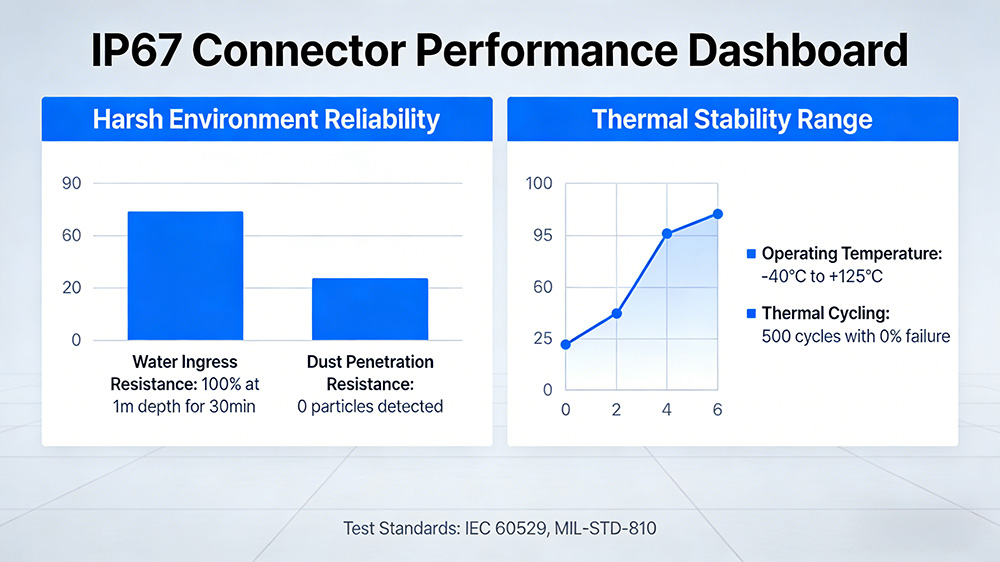

5.1 Reliability in Wet and Dusty Environments

IP67 connectors maintain clear, uninterrupted signal transmission even in the mud, dust, and moisture of agricultural equipment operation—eliminating corrosion-induced data loss. They power outdoor LED displays through rainstorms and protect marine electronics from salt spray, drastically reducing costly repair calls and unplanned downtime.

Independent testing shows IP67 connectors reduce equipment downtime by up to 50% in harsh environments, while cutting maintenance costs and preserving consistent signal strength—even when fully wet.

· Agricultural machinery: Fewer breakdowns during critical harvest seasons

· Outdoor LED displays: Uninterrupted illumination through rain and snow

· Marine electronics: Corrosion-free performance in saltwater spray

5.2 Thermal Stability and Operational Range

Extreme heat and cold cause thermal expansion/contraction of internal components, a leading cause of connector failure. IP67’s hermetic sealing stabilizes internal pin contacts, preventing loosening, arcing, or signal interference due to temperature shifts.

High-quality IP67 connectors operate across an extreme temperature range of -55°C to 125°C, while standard connectors typically top out at 70°C—warping and failing rapidly in extreme thermal conditions.

In high-heat engine bays or subzero cold storage warehouses, this thermal stability is critical: IP67 seals remain pliable and effective, keeping internal components dry and contacts secure.

6. Implementation and Maintenance: Choosing and Leveraging IP67 Solutions

When selected, installed, and maintained correctly, IP67 connectors deliver years of trouble-free performance with minimal upkeep. Success hinges on attention to key details during implementation.

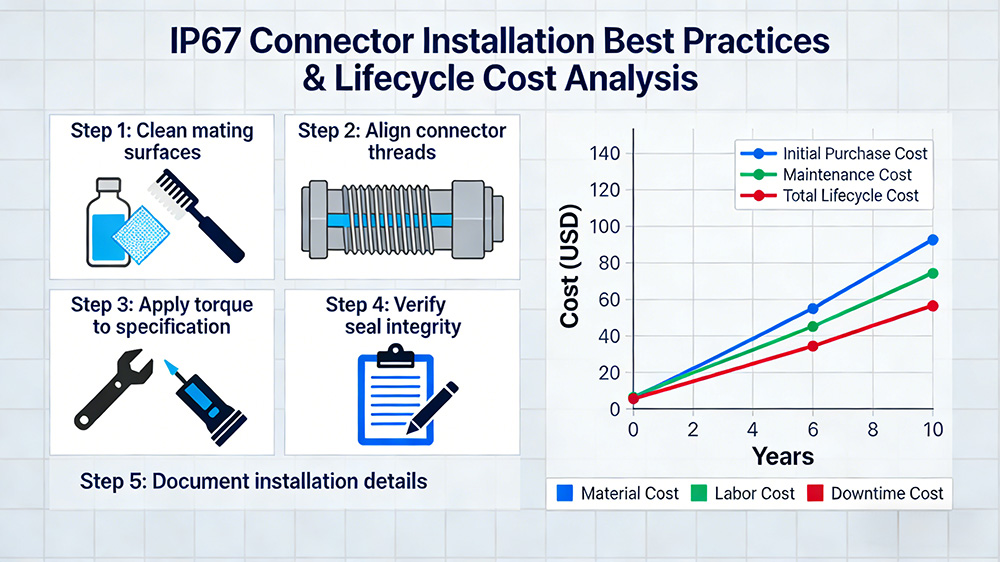

6.1 Installation Best Practices for Maintaining the Seal

Proper installation is critical to preserving the IP67 seal—follow these core steps:

1. Tighten coupling nuts to the manufacturer’s specified torque: Under-tightening creates seal gaps, while over-tightening crushes sealing components and causes permanent damage.

2. Align mating parts straight before connection: Debris on pins or misalignment can damage seals and create entry points for water/dust—clean pins with compressed air or a lint-free cloth first.

3. Conduct a post-installation leak test: A quick water spray check identifies seal issues early, before they lead to operational failure.

4. Secure connectors with locking mechanisms (if included) to prevent accidental disconnection and maintain seal integrity.

6.2 Lifecycle Cost Analysis: Investment vs. Replacement Frequency

IP67 connectors carry a modest upfront premium—typically 20-30% more than standard unrated options—but deliver a 5-10x longer service life, drastically reducing replacement frequency and associated labor costs.

Industry data confirms IP67 connectors boost MTBF (Mean Time Between Failures) from 1,000 hours (standard connectors) to 10,000 hours or more, cutting maintenance labor by up to 50%. A real-world example: a manufacturing plant that switched to IP67 connectors reduced unplanned downtime by 40%, resulting in thousands of dollars in annual cost savings—with the initial upfront investment recouped in just a few months.

7. Conclusion: Future-Proofing Connectivity with Ingress Protection

IP67 connectors outperform standard alternatives in dust resistance, water protection, and mechanical stress tolerance, thanks to engineered sealing and high-grade materials that deliver genuine, field-tested reliability. Across agriculture, manufacturing, marine, and outdoor tech, IP67 connectors reduce downtime, cut maintenance costs, and eliminate the financial risks of faulty connectivity.

Don’t compromise on performance in harsh environments—specify IP67-rated connectors for all critical applications. Verify IP ratings clearly when sourcing components to ensure compliance with your operational needs. With IP67, your systems will run smoothly and reliably for the long term; upgrading now is an investment in hassle-free connectivity and bottom-line savings.